EGO Appliance Controls: a three-system combo maximises productivity

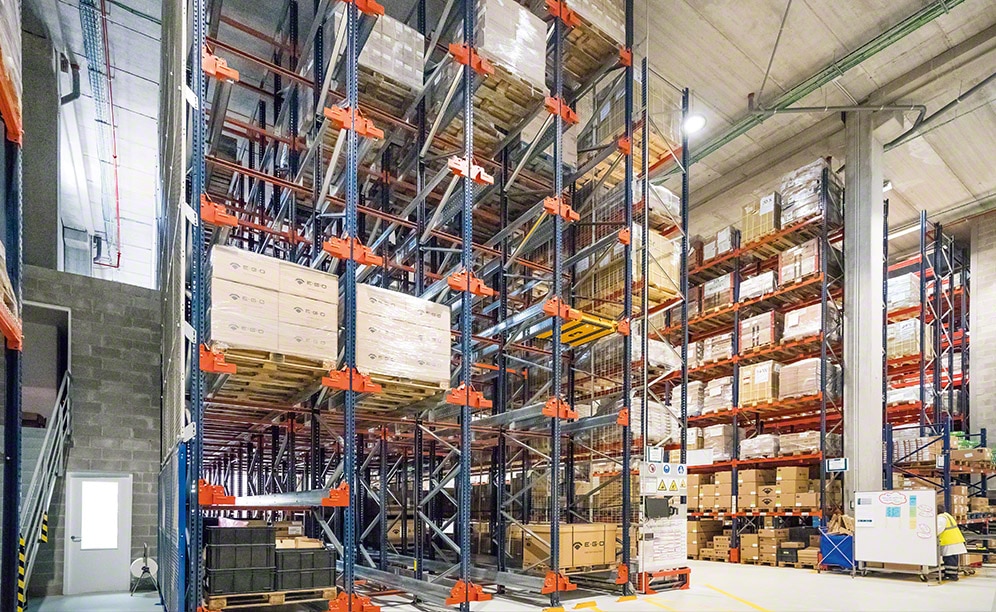

The triple storage system makes the most of the available storage area in the warehouse of EGO Appliance Controls

EGO Appliance Controls obtained a solution tailored to its needs in the warehouse it owns in Lliçà de Vall (Barcelona). Mecalux equipped the facility with the high-density Pallet Shuttle system, two blocks of Movirack mobile racks and pallet racking.

About EGO

Founded in 1931, EGO has built up a specialised business model that includes, among other things, control components and engine management systems for domestic and industrial devices like washing machines, clothes dryers and dishwashers. Its business dealings also extend into other applications, such as for kitchens and refrigeration, as well as household, industrial and business settings.

Currently, it sells more than 20,000 different products in 16 countries.

Three storage systems

The storage space EGO owns and operates in its centre in Spain was a tight fit when faced with growing demand. The business required more capacity without a drop in operating speeds. Likewise, it was crucial to keep the wide variety of products available, as well as its multiple high, medium and low turnover SKUs.

Mecalux has supplied two compact storage systems: a block with the semi-automatic Pallet Shuttle for consumer products and another two Movirack mobile racks, one in front of the other, for medium and low consumption products. At the same time, Mecalux made use of the aisle created between the two blocks by installing pallet racks there.

Pallet Shuttle system

The 82 m2 block with the semi-automatic Pallet Shuttle system comprises 25 channels that are 14 m long and able to store 16 pallets deep. Overall, the storage capacity is 448 pallets of 800 x 1,200 mm with a 500 kg unitary weight.

To store the goods, the operator places the electric shuttle in the corresponding channel by means of a reach truck. Next, they set the pallets in the channel’s entry point, and the Pallet Shuttle moves it to the first open location. The shuttle returns to the home position in order to repeat the operation with the next pallet. This sequence is repeated as many times as needed. The same process is carried out in reverse from the opposite side of the block of racks to remove the goods.

This block of racks operates with the FIFO criterion (first in, first out), in other words, the first pallet to enter is the first to leave. Goods slotted into one side of the aisle are extracted from the other side, obtaining excellent turnover and preventing interference between the loading and unloading of the pallets.

The tablet

Operators run the automatic shuttles via a Wi-Fi connected tablet. This tablet has a very intuitive software that does not require specific training and can carry out multiple applications and functions, including:

- Uninterrupted loading and unloading of channels.

- Automatic stock keeping of the number of stored pallets.

- User and authorised personnel management.

- Activation of the locking system, which enhances the bond between the Pallet Shuttle and the handling equipment’s forks and prevents it from accidentally falling.

Movirack mobile racking

Two blocks of Movirack mobile racks are installed in which the company houses 1,680 pallets of 800 x 1,200 mm with a maximum 500 kg unit weight. Each block consists of three, double-depth racks on mobile bases down the centre and two stationary ones at the ends.

This high-density system is a game changer, as far as space goes. It compacts the number of aisles, as well as eases direct access to the goods when the corresponding work aisle opens.

Both blocks run automatically. The operator sends the required open aisle command through an RF remote control to extract or deposit the goods, and also to pick directly from pallets located on lower levels.

To assure the safety of the goods and, above all, of the operators, the Movirack system includes optoelectronic devices or light curtains, longitudinal photocell sensors placed bilaterally on the bases, as well as emergency stop and reset buttons.

Pallet racking

The four blocks of pallet racks can accommodate 287, 800 x 1,200 mm sized pallets. Each pallet can weigh up to 500 kg.

It is a very versatile system, which adapts to any unit load type, able to house heavy pallet and those with variable volumes. Direct access to products streamlines the management of goods and order picking.

Reach trucks are the primary handling equipment operated in this warehouse to insert and extract pallets from their locations.

Advantages for EGO Appliance Controls

- High storage capacity: the triple storage system makes the most of the available storage area, thus achieving an overall 2,415 pallet capacity.

- Adaptable to many different products: the combination of three systems eases the sorting of a huge variety of products according to their characteristics and turnover.

- Safety first: the storage system includes safety devices that ensure the installation runs smoothly and safely.

| Racks with Pallet Shuttle | |

|---|---|

| Storage capacity: | 448 pallets |

| Pallet size: | 800 x 1,200 mm |

| Max. pallet weight: | 500 kg |

| Max. racking height: | 11 m |

Gallery

Mecalux equipped the facility with the high-density Pallet Shuttle system, two blocks of Movirack mobile racks and pallet racking

Ask an expert