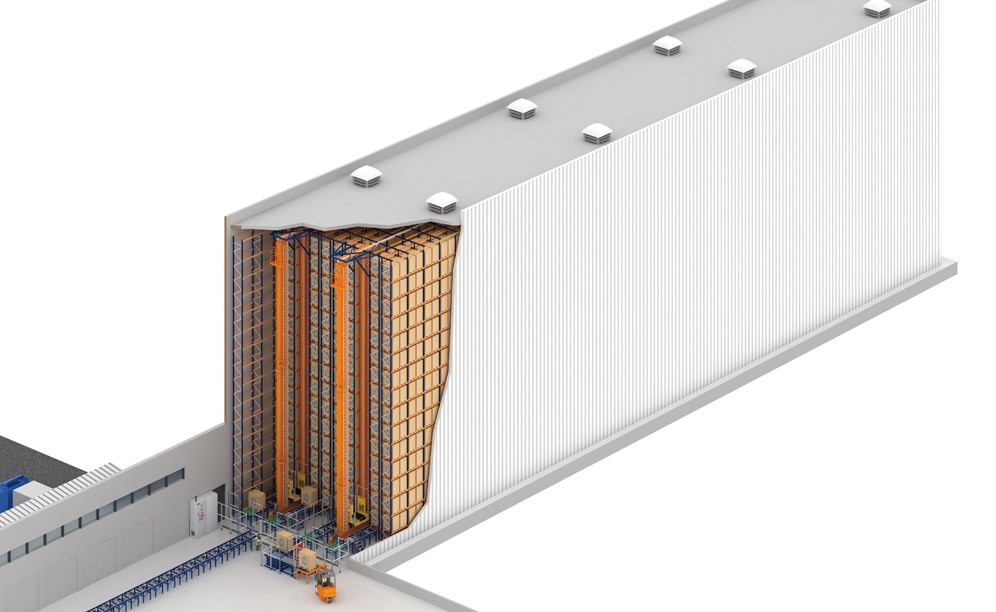

A 20 metre high clad-rack automated warehouse for the Brazilian pharmaceutical company Novamed

Novamed completely automates storage, transport, and management

Mecalux designed and installed for Novamed, a Brazilian company specialising in the production of solid medications, a high-performance clad-rack automated warehouse in the city of Manaus (Brazil). The provision has also included the warehouse management software the Mecalux Easy WMS, and the Galileo control programme.

About Novamed

Novamed, under Group NC (leader in the Brazilian pharmaceutical sector, ranking second in Latin America), was established in 2009 as a company specialised in the supply of medication. After strong initial growth, in 2014 Novamed built one of the largest and most modern medicine factories in the world, becoming the first pharmaceutical company in the history of the Free Economic Zone of Manaus, Amazonas.

On an initial 250,000 m² plot, it has built a 35,000 m² modern complex providing 500 jobs, a production centre which manufactures 1.5 billion tablets a month and a complete and efficient automated warehouse.

A clad-rack warehouse as a solution

Novamed needed a warehouse that was close to its production centre, and which could accommodate the large number of products it works with. In addition, it was essential to automate the internal transport of goods to manage a large number of SKUs in the most efficient way possible.

The solution proposed by Mecalux was to build a 20 m high clad-rack automated warehouse located next to the production premises. Inputs from production are carried through a conveyor circuit connecting the front of the warehouse, while outputs are performed by an independent circuit.

The warehouse contains the following:

- Storage area

- Inbound goods area

- Outbound goods area

- Rejects area

- Traditional cold-storage

In a clad-rack warehouse, the structure of the building is formed by the racks themselves and the outer cladding is coupled to them.

For the structural design of a clad-rack warehouse, the weight of the racking is taken into account, that of the stored goods, wind forces both pressure and suction based on the area where it is built, the thrust of the stacker cranes and, finally, the corresponding seismic activity of the territory in which it is located.

Inside the warehouse

Thanks to an optimal use of space, the Novamed warehouse has a storage capacity of over 4,000 pallets in an area of only 845 m².

The installation consists of two 58.7 m aisles with double-deep racking enabled on both sides and composed of 23 bays and 11 load levels each. An automatic stand-alone stacker crane runs in each aisle, which handles the pallets stored.

The stacker cranes have a single-mast and incorporate a maintenance cabin, which is located in the lifting cradle itself. The use of stacker cranes helps increase productivity, while decreasing the resources required to handle the goods.

Inputs and outputs: the conveyor circuit

Incoming palletised goods from production are carried by means of the main conveyor circuit, which connects with the storage aisles via a transfer car. The entrance area includes three checkpoints that are responsible for verifying that the dimensions, weight and status of the pallets meet the specifications of the installation.

Outputs are produced by means of an independent circuit that also connects with the warehouse's transfer car.

WMS: Mecalux Easy WMS and Galileo

Mecalux has implemented the warehouse management software the Easy WMS: the mastermind that governs all operations from production to dispatch.

This powerful system performs, among others, the following functions:

- Input management of the goods from the production lines.

- Location of pallets in the warehouse via previously parametrised rules under the following criteria: type of product, space optimisation and maximum productivity.

- Stock management and warehouse layout (which goods and where they are).

- Preparation of preloads according to the required order and the subsequent loading onto trucks.

- Status queries of the different parts of the warehouse and the equipment operating in it.

- Thanks to the Galileo control module, all movements of the different equipment within the whole installation are managed, as well as their security measures.

The communication between Easy and the customer's ERP is permanent and bidirectional, transferring the data both systems need to effectively operate and manage the warehouse. The success of the installation depends on this connection.

Advantages for Novamed

- Maximum capacity in a small space: Novamed can store 4,048 pallets of 1,000 x 1,200 mm in an area of only 845 m².

- Increased productivity: there is enhanced warehouse efficiency by automating storage processes.

- Improving safety in the installation: operators do not work within the aisles. Therefore, the system is more secure and the risk of accidents is reduced.

- Efficient management: thanks to the Mecalux Easy WMS warehouse management system and the Galileo control system, Novamed manages all the flows, processes and operations that take place within its warehouse.

| Clad-rack automated warehouse for Novamed, Brazil | |

|---|---|

| Storage capacity: | 4,048 pallets |

| Pallet size: | 1,000 x 1,200 mm |

| Max. pallet weight: | 750 kg |

| Warehouse height: | 20 m |

| Load levels: | 11 |

| No. of stacker cranes: | 2 |

| Type of stacker crane: | single-mast |

| Fork type: | double-depth |

| Constructive system: | clad-rack |

Gallery

Mecalux designed and installed for Novamed a 20 m high clad-rack automated warehouse in Brazil

Ask an expert