Smart management of Brasserie de Vezelay craft beer in France

The craft beer brewery Brasserie de Vézelay has upgraded its logistics with Easy WMS by Mecalux

Organic craft brewery Brasserie de Vézelay’s warehouse in Saint-Père (France) has boosted the productivity of its operations by installing the Mecalux Easy WMS management system (WMS). Smart management by this WMS is essential for the warehouse to supply the production area with the necessary raw materials while simultaneously distributing the finished products to customers.

A beer with history

When he was about to turn 50, Marc Neyret decided to break with his routine and his position as director of human resources at a major telephone company and embark on a new challenge: brewing his own craft beer.

After meeting Stefan Stadler, a master brewer based in Denmark, he obtained valuable advice on how to produce high-quality craft beer. Brasserie de Vézelay beers are brewed in accordance with the so-called “law of purity” —Reinheitsgebot, in German— and are therefore made solely from water, malt and hops, with no added sugars, artificial colours or other additives.

Storage of craft beer

Since its creation in 2012, Brasserie de Vézelay has achieved great success amongst beer lovers. Its beverages have been awarded numerous prizes in competitions such as the World Beer Awards and the Paris Agricultural Competition, which has helped it to earn a stellar domestic and international reputation.

To become more competitive and meet the needs of its customers efficiently, Brasserie de Vézelay has prioritised and modernised its logistics. It has thus opened a 600 m2 warehouse in Saint-Père (France).

The warehouse has a dual purpose: to supply production with raw materials at the right time, and to receive finished products ready to be sent to customers.

In the midst of strong production and sales growth, the company has been forced to bolster storage and picking. At the end of 2018, with the commissioning of its new warehouse, they found it necessary to implement software that would guarantee traceability and optimise operations.

That is why Brasserie de Vézelay has installed the Mecalux Easy WMS warehouse management system (WMS), a software system that coordinates the entries and exits of goods and supplies the production area without interruption. Marylène Trouillot, the company’s administrative manager, exclaims that “the commissioning was excellent, professional and competent. The Mecalux team accompanied us at all times during the first few months of use, which we very much appreciate”.

The company has opted for the cloud-based mode, i.e. SaaS (Software as a Service). Easy WMS has a 100% online interface, through which one can access their applications from any browser with maximum security. In this regard, Marylène Trouillot comments that “we chose this solution because it did not require a hardware investment, is very easy to use, and includes automatic backups and periodic software updates”.

The Brasserie de Vézelay warehouse manages more than 70 SKUs, including finished products and raw materials. Some raw materials (mainly hops and yeast) need to be kept at a controlled temperature.

To avoid any mistakes, products are identified by a barcode from the moment they arrive at the warehouse. The system assigns a slot to these products, taking into account different variables, such as product type, rotation, or dimensions. Thus, for example, completed orders are grouped in the same warehouse area, while raw materials are grouped in another. The WMS monitors stock status and the exact location of all items in real time.

Marylène Trouillot y Sophie Naudé - Administrative manager and production manager at Brasserie de Vézelay

“We are very satisfied with the investment we have made. Easy WMS, and all the equipment installed by Mecalux, meet our expectations. Mecalux has provided us with a comprehensive approach, from commercial to after-sales service. Implementing Easy WMS has helped us structure and improve our processes”.

Warehouse connected to production

One of Easy WMS’s main functions is to ensure that operators can move raw materials into production whenever required. Any delay would make it necessary to interrupt beer production, something that is out of the question for Brasserie de Vézelay.

To prevent this situation, Easy WMS communicates with Brasserie de Vézelay’s ERP EBP via XML files and, as a result, the warehouse is able to meet production needs instantly. ““One of the strong points of Mecalux’s Easy WMS is the fact that it interacts with our ERP EBP software and that Limpid IT, the ERP integrator, guarantees there is a good interface between the two software programs,” explains Marylène Trouillot.

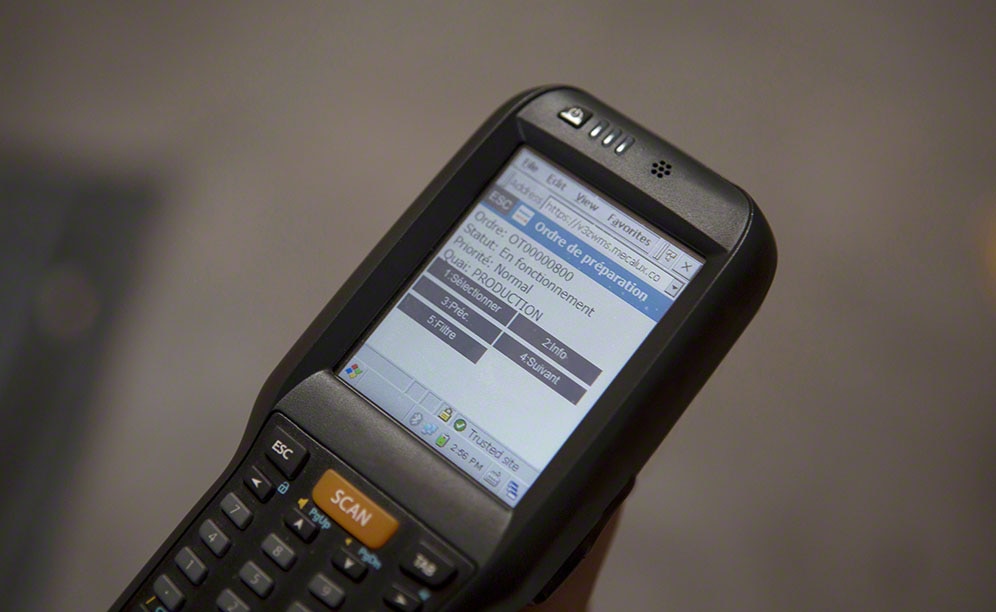

The work done by operators is also indispensable for supplying production. They follow Easy WMS instructions with the help of RFID terminals. They use these devices to communicate with the WMS and receive orders, and to confirm that they have been fulfilled. This working method speeds up entries and exits of goods, preparation of orders and the dispatch of raw materials to production: “our logistics system has been simplified; it’s smoother, and we’ve saved time in each of the processes,” said the company’s administrative manager. Marylène Trouillot also adds that “after several months of use, the operators have already adapted to the operation of the software. They appreciate the benefits and, thanks to the instructions, they are better able to carry out storage and picking tasks”.

Multiple orders are prepared daily. To do this work, the WMS tells them which storage spot to go to, what SKUs to locate, and how many to extract. Thanks to Easy WMS supervision, the company has drastically reduced the number of picking mistakes and has increased the frequency with which orders are sent.

WMS ready to grow

With the incorporation of Mecalux’s Easy WMS, Brasserie de Vézelay has a productive warehouse with much more efficient and error-free operations. The company has centralised its logistics at a single warehouse, where it stores raw materials and finished products As a result, it is able to provide the service its customers expect.

Although beer is a beverage consumed throughout the year, sales do tend to jump with the arrival of good weather. This has repercussions on the pace of production and, therefore, on the operations of the warehouse and the length of time the goods remain there. Easy WMS is a tool capable of adapting to changes, heightened demand, and the incorporation of new processes. The WMS is also prepared to grow and accompany Brasserie de Vézelay in any future expansion project.

Advantages for Brasserie de Vézelay

- Warehouse connected to production: Easy WMS, connected to the ERP EBP of Brasserie de Vézelay, supplies production with the necessary raw materials at the right time.

- Traceability of goods: products are identified from the moment they arrive at the warehouse. WMS thus knows the exact location of the goods in real time.

- Optimisation of operations: the WMS simplifies the work of operators, by designing a route through the warehouse when goods need to be picked and stored.

Gallery

The operators use radiofrequency terminals to communicate with WMS

Ask an expert